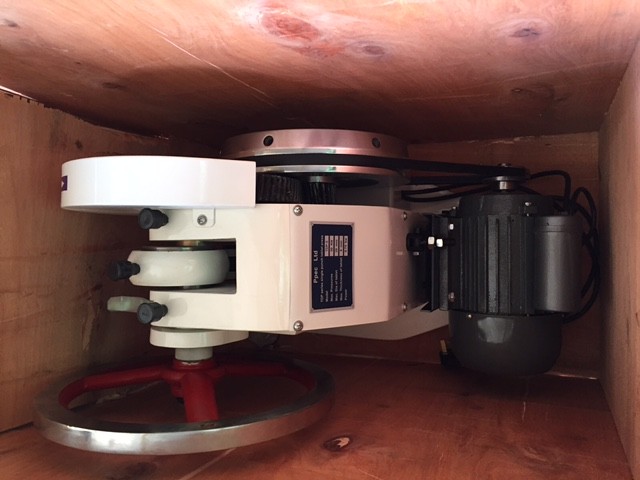

About the TDP-5

Tablet Press 5 is a flexible, lightweight tablet press that is utilized for compacting granulated and powdered materials into tablets. Its minimal outline makes it perfect for little batch production or trial runs. However, its little size doesn’t lessen its energy. It runs easily using electricity, or by hand if that is sought. It doesn’t just create round tablets, however, can deliver tablets of any shape and can even imprint images or other outlines on a tablet.

Advantages:

Lightweight

Presses tablets of any shape

Low-maintenance

Compact

Quick and solid

High yield

Product Details:

As a single punch press machine, one and only set of punch dies can be installed. The machine can be utilized as a part of numerous sectors and is commonly found in pharmacies, the chemical industry, food services, medical establishments and other sectors. TDP 5 can work with various materials including sugar, calcium, and various tablets. It produces tablets of all sizes, the biggest being 22 mm in diameter. The thickness of the tablet and filling depth of the material are both flexible. The most extreme filling depth is 15 mm. This machine delivers more than exclusively round tablets by using diversemolds.

If you have the mold, you need for your pill; the machine can create a pill of that shape and outline. TDP 5 has the most astounding yield limit of the reach, and can deliver up to 5,000 units per hour. It can be utilized viably for thought process and continuous sheeting. The greatest pressure this machine produces is 50 km. While the TDP 5 contains more stamina than the TDP 1, the item size is just 65 cm x 44 cm x 65 cm. Its little size doesn’t modify it’s a high exactness of filling, its low noise, and the low-utilization of material. The minimum use of lab materials is just 200 g. While this machine can be utilized for some things, it is not, for the most part, recommended for mass production. It works most effectively in the lab or for improvement forms in certain industries.

The machine is incredibly easy to utilize, regardless of the fact that you decide to the make the pills out by hand. To start with, you put the crude materials in the cone-formed container. Next, you get a handle on the handle firmly and delicately turn. Your recently made tablets ought to show up shortly and are prepared to be packaged. It’s a straightforward procedure that anybody can learn rapidly. If you would prefer not to consume your vitality cranking out pills then essentially connect to your machine, and it will finish the same procedure using electricity.

In short, this machine is perfect for trial runs and developing new pills. It’s smaller and solid, effective and dependable. Its size does not restrain its production or its capacity to deliver an assortment of shapes and plans for your pill. This machine is the response to your need to deliver well-formed tablets.

Remarks:

This device accompanies a set of round no-logo punch dies. If you require making another logo, we likewise provide customization.

Read instructions thoroughly before setting up the machine for the first run through.

This machine should only run towards one direction. Reversing the course will harm accessories.

While connecting electricity, the upper punch should be at its most astounding position to shield from damaging to the machine.

Specifications:

| Name | Value |

| Product | TDP-5 |

| Number of Dies | 1 |

| Max Pressure (KN) | 50 |

| Max Diameter of Tablet | 20 |

| Max Fill Depth | 12 |

| Max Thickness of Tablet | 6 |

| Max Production Capacity Per Hour | 5400 |

| Number of Filling Stations | 1 |

| Double Layered Tablet | No |

| Motor (Kw) | 0.55 |

| Number of Phases | 1 |

| Amp’s | 13 |

| Volts | 240v (110v on request) |

| Height (Mm) | 800 |

| Width (Mm) | 400 |

| Depth (Mm) | 700 |

| Weight (Kg) | 125 |

Reviews

There are no reviews yet.